Gone are the days when you relied on the traditional and manual tracking systems within your organisational warehouses. Today’s world is moving away from these old-age methods, understanding the errors they can make while helping with product picking and tracking. However, there should be a robust solution for organisations to effectively respond to rapid changes in the digital world, as the warehouse is an essential part of the company. This is where ‘RFID Warehouse Management’ enters the scenario as the ideal companion in warehousing.

In this article, we explore how RFID is used in warehouse management and how the RFID asset tracking system Singapore helps your organisation with its powerful automation to improve operational efficiency and meet consumer demands in the dynamic market.

We will explore

What is RFID Technology?

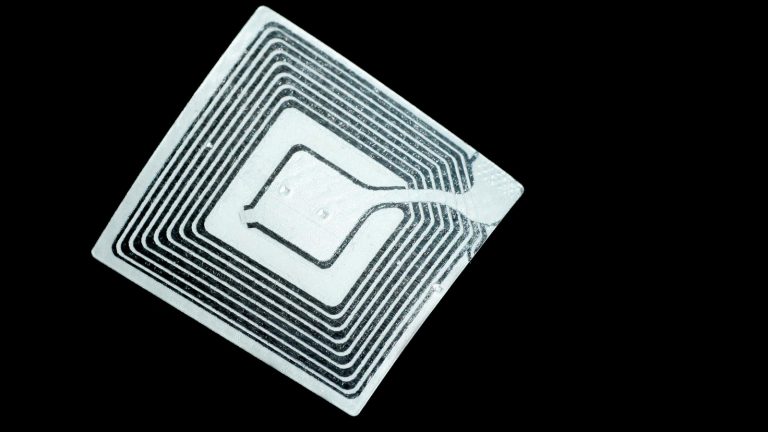

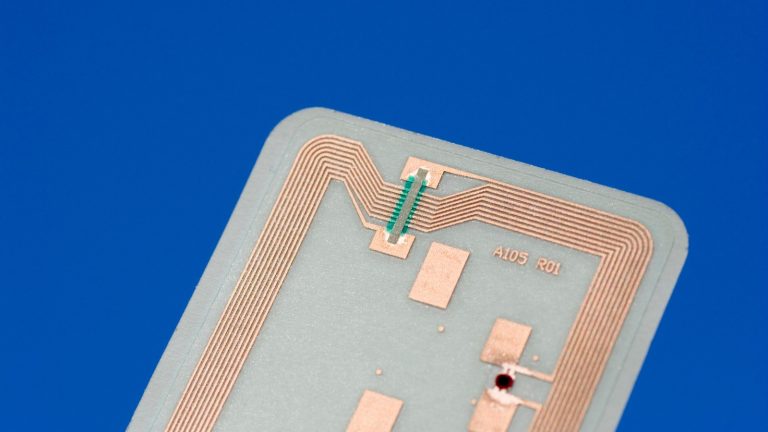

- Radio-frequency identification is what is known as RFID in the technological world. This technology is an automatic wireless recognition technology that employs electromagnetic waves to automatically identify and track tags attached to objects.

- In modern warehouses, RFID is integrated into inventory management systems to enhance efficiency and accuracy.

- RFID tags, equipped with unique identifiers, are attached to items or pallets in order to help with real-time tracking throughout the supply chain. This has become popular as secure identification software due to its ability to provide relevant information in real time regarding warehouse items.

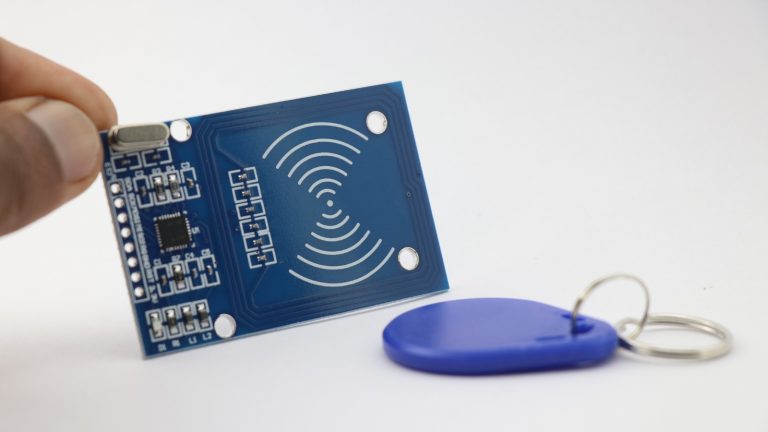

- This is a bit different from traditional barcode scanning. RFID does not require line-of-sight scanning and allows for simultaneous reading of multiple tags. This makes RFID ideal for environments where rapid and hands-free identification of items is crucial. It also drastically speeds up processes like receiving, picking, and shipping.

- Considering its outstanding capacity, RFID has been embedded into various software solutions ranging from Warehouse Management solutions Facilities Management, RFID Asset Management and Tracking, RFID Inventory Tracking and mobile RFID around Singapore.

What is a Warehouse Management System?

- A Warehouse Management System or WMS, is a software application that helps businesses efficiently manage and control warehouse operations.

- It can indeed carry out various tasks, such as inventory management, picking, packing, shipping, and receiving. Due to innovations in the technological world, WMS nowadays utilises technology like barcode scanning, RFID, and automation to optimise warehouse processes and improve overall efficiency.

- In a traditional warehouse setup, tasks are often manual and rely heavily on paper-based systems or basic inventory management software. This can lead to inefficiencies, errors, and limited visibility into inventory levels and movements.

- This is why the new-age warehouse management has moved away from them and implemented new developments for better results. RFID-based solutions are the most popular choice when it comes to WMS implementations. With the help of warehouse tracking systems, it provides real-time visibility into inventory, expedites workflows, automates tasks, and enhances accuracy through advanced features like inventory tracking, labour management, and reporting capabilities.

- WMS can store data that is streaming through tracking devices like RFID and beautifully automate transactions. This is why more and more companies in Singapore are now relying heavily on it.

Top 5 Benefits of RFID Warehouse Management for Singapore

Minimising Losses and Shrinkage

RFID warehouse technology helps minimise losses and shrinkage as it can provide accurate and timely information about all inventory movements.

With a broad range of reliable, end-to-end RFID solutions like tags attached to individual items or pallets, warehouse managers can track the location and status of goods in real time. This helps with the quick detection of unbalances between expected and actual inventory levels. Plus, it allows for immediate investigation and intervention in cases of theft, misplacement, or damage.

The most important thing is that RFID technology offers secure access control, which limits unauthorised access to high-value items or restricted areas within the warehouse. With this system in hand, you can have better asset visibility through enhanced tracking. Boosting accountability throughout the supply chain, RFID helps deter theft, reduce losses, and minimise shrinkage.

When you have a good understanding of the actual status of your inventory, it will be a great help for you to make timely decisions. Also, it backs up faster inventory management, which leads to greater business productivity.

Just-in-Time Inventory Management

RFID Warehouse Management facilitates Just-in-Time (JIT) inventory management by providing real-time visibility into inventory levels and movements. RFID tags attached to all items carry out the task of accurate tracking of inventory throughout the entire supply chain with 100% certainty.

This real-time data allows warehouse managers to monitor inventory levels closely and foresee demand fluctuations more effectively. With RFID, organisations can implement JIT strategies by maintaining optimal stock levels without overstocking or understocking.

Since the system empowers you with automated data entry capacity, it easily tracks inbound and outbound shipments as well. RFID systems ensure that inventory is restocked precisely when needed. This paves the way to stay away from the burden of excess inventory carrying costs and reduce the risk of stockouts.

It is highly visible that RFID backs up more efficient order processing and fulfilment, allowing businesses to respond quickly to customer demands and fluctuations in Singaporean market conditions.

As you can see, reduced inventory errors lead to increased efficiency levels within your organisational warehousing framework.

Optimised Space Utilisation

Space has been one of the major headaches for warehouse managers in Singapore. There can be limited space inside your warehouse for certain reasons. However, RFID warehouse management is the ideal answer for this matter, and this is the main reason most warehouse managers prefer RFID warehouse management in the first place.

It contributes to optimised space utilisation by providing real-time visibility and insights into inventory levels and storage space availability.

It is common that different industries, ranging from commercial and industrial to government and logistics, have to maintain up-to-date warehouse management for better results. They might have single locations or larger operations with multiple sites. This technology easily takes care of both the front-end and back-end infrastructures of your warehouse facility.

With RFID tags attached to items or pallets, warehouse managers can accurately track the location and movement of goods within the facility. This data allows for more efficient placement of inventory, maximising the use of available storage space.

Let us explain how this happens. Since the software can dynamically allocate storage locations based on real-time inventory data, RFID systems help prevent overstocking in certain areas and underutilisation in others.

It goes without saying that the advanced analytics of the software help you optimise the products according to demand. It shows where high-demand items are strategically placed for easier access and faster retrieval.

Reduced Errors

RFID-based solutions reduce errors in tracking and product picking, and this occurs due to their power to automate data capture and provide real-time visibility into inventory movements.

With RFID tags attached to items or batches, warehouse employees can accurately identify and locate products without manual scanning. This eliminates human error associated with barcode scanning. With this system in hand, RFID readers can be strategically placed throughout the facility to automatically detect tagged items as they move through various stages of the warehouse process. The latter ensures that inventory counts are precise and up-to-date.

In one way, RFID technology minimises picking errors by guiding workers to the correct items through the use of handheld RFID readers or pick-to-light systems. In another way, it helps reduce management man-hours and labour costs to a significant level. In the end, it clears the way to increase revenues at a lower cost.

Enhanced Security

Security poses the number one threat in the realm of corporate warehouses in Singapore.

However, an RFID-embedded warehouse management system provides a helping hand for you to solve this concern. It ensures the security of products by offering precise identification and tracking of items throughout your supply chain, from A to Z.

RFID tags, equipped with unique identifiers, allow for accurate inventory monitoring, allowing rapid detection of theft or misplaced items. If an item with an RFID tag is moved without authorisation or leaves a designated area, the system triggers an alert, notifying warehouse employees of the unauthorised activity.

Furthermore, RFID technology offers the capability of access control by restricting entry to sensitive areas or high-value inventory zones only to authorised personnel with RFID-enabled badges or credentials.

If it spots a security breach, the RFID Warehouse Management system can automatically generate alerts via email, text message, or notification within the management software. It is clearly visible that this solution is scalable and can flexibly support the prevention activities of potential security threats.

Enhancing the Productivity of Warehouses in Singapore Through RFID Technology

Since you have read the full article, you know how RFID is used in warehouse management systems. However, RFID consulting and implementation is not something you should take lightly, as it covers all aspects of your warehouse management. This is the main reason you must think twice before making a rapid purchase decision. It is always advisable to collaborate with a software partner who has a track record of RFID implementations in Singapore. With the right strategies implemented, your business growth will be unstoppable, for sure.